Business Inventory Book: Mastering the art of inventory management is crucial for any business, regardless of size. This comprehensive guide delves into the intricacies of maintaining accurate inventory records, from understanding the fundamental purpose of an inventory book to employing advanced inventory costing methods and leveraging technology for efficient tracking and reporting. We will explore various inventory management techniques, including FIFO, LIFO, and weighted-average cost, and provide practical examples and actionable strategies to optimize your inventory processes.

Prepare to transform your inventory management from a tedious task to a strategic advantage.

We’ll cover everything from designing a basic inventory book for a small retail business to utilizing sophisticated software solutions for larger enterprises. The goal is to equip you with the knowledge and tools to effectively manage your inventory, minimize costs, and maximize profits. Whether you prefer manual methods or embrace digital solutions, this guide provides a flexible framework adaptable to your specific business needs and growth trajectory.

Defining a Business Inventory Book

A business inventory book serves as a crucial record-keeping tool, providing a comprehensive overview of a company’s assets. It’s essential for effective management, accurate financial reporting, and informed decision-making. Maintaining an up-to-date inventory book allows businesses to track stock levels, identify slow-moving items, and optimize purchasing strategies, ultimately contributing to improved profitability.The purpose of a business inventory book is to accurately track the quantity, value, and location of all goods held by a business.

This data is vital for various business functions, including sales forecasting, order fulfillment, and preventing stockouts or overstocking. It also forms the basis for calculating the cost of goods sold (COGS) and accurately reporting inventory values on financial statements.

Key Components of a Well-Designed Inventory Book

A well-designed inventory book should include several key components to ensure accuracy and efficiency. These components contribute to a clear and readily accessible record of inventory movements. Missing any of these components can significantly hamper inventory management and financial reporting.

- Item Identification: A unique identifier for each item, such as a SKU (Stock Keeping Unit) number or product code.

- Item Description: A clear and concise description of the item, including size, color, and any other relevant specifications.

- Quantity on Hand: The current number of units in stock.

- Unit Cost: The cost of each individual item.

- Total Value: The total value of the item in stock (Quantity on Hand x Unit Cost).

- Date of Purchase/Receipt: The date when the items were received.

- Supplier Information: Details about the supplier from whom the items were purchased.

- Location: The storage location of the inventory.

- Reorder Point: The inventory level at which a new order should be placed.

- Transactions: A record of all inventory transactions, including receipts, sales, and adjustments.

Types of Inventory Books for Various Business Sizes

The optimal inventory book system varies greatly depending on the size and complexity of a business. Small businesses might find simple spreadsheets sufficient, while larger enterprises require sophisticated software solutions. The choice should align with the business’s needs and resources.

- Spreadsheet (e.g., Excel): Suitable for very small businesses with limited inventory. Offers basic tracking capabilities but lacks advanced features.

- Simple Database Software (e.g., Access): Provides better organization and search capabilities than spreadsheets, suitable for small to medium-sized businesses.

- Inventory Management Software (e.g., QuickBooks, Zoho Inventory): Offers comprehensive features including barcode scanning, automated ordering, and reporting functionalities, ideal for medium to large businesses.

- Enterprise Resource Planning (ERP) Systems: Integrated systems managing all aspects of a business, including inventory, suitable for large enterprises with complex inventory needs.

Manual vs. Digital Inventory Book Systems

The choice between manual and digital inventory systems involves weighing the benefits and drawbacks of each. Manual systems are simpler to set up but prone to errors and inefficiencies, while digital systems offer greater accuracy and scalability but require a technological investment.

| Feature | Manual System | Digital System |

|---|---|---|

| Accuracy | Prone to human error | Generally more accurate |

| Efficiency | Time-consuming, especially for large inventories | More efficient, automates many tasks |

| Scalability | Difficult to scale with business growth | Easily scalable to accommodate increasing inventory |

| Cost | Low initial cost | Higher initial cost due to software and hardware |

| Reporting | Limited reporting capabilities | Provides detailed reports and analytics |

Sample Inventory Book Layout for a Small Retail Business

This example demonstrates a simple layout suitable for a small retail business using a spreadsheet or simple database. It focuses on key information necessary for effective inventory tracking.

| SKU | Item Description | Quantity on Hand | Unit Cost | Total Value | Date Received | Supplier | Location | Reorder Point |

|---|---|---|---|---|---|---|---|---|

| ABC123 | Blue T-Shirt (Small) | 50 | $10 | $500 | 2024-03-01 | Supplier X | Shelf A | 20 |

| DEF456 | Red T-Shirt (Large) | 30 | $12 | $360 | 2024-03-15 | Supplier Y | Shelf B | 15 |

| GHI789 | Jeans (Medium) | 25 | $25 | $625 | 2024-02-28 | Supplier X | Shelf C | 10 |

Inventory Management Methods

Effective inventory management is crucial for a business’s financial health. Accurate tracking and valuation of inventory directly impact profitability, tax liabilities, and overall operational efficiency. Choosing the right inventory costing method is a key component of this process, influencing the reported cost of goods sold and the value of ending inventory. This section details three common inventory costing methods: First-In, First-Out (FIFO), Last-In, First-Out (LIFO), and Weighted-Average Cost.

First-In, First-Out (FIFO)

FIFO assumes that the oldest inventory items are sold first. This method aligns well with the physical flow of goods in many businesses, particularly those dealing with perishable goods. Using FIFO, the cost of goods sold reflects the cost of the oldest inventory, while the ending inventory reflects the cost of the most recently acquired items.For example, imagine a bakery that bakes 10 loaves of bread on Monday at a cost of $2 each, and another 10 loaves on Tuesday at $2.50 each.

If they sell 15 loaves during the week, the cost of goods sold under FIFO would be calculated as (10 loaves

- $2) + (5 loaves

- $2.50) = $32.50. The value of the remaining 5 loaves in ending inventory would be 5 loaves

- $2.50 = $12.50.

Last-In, First-Out (LIFO)

LIFO assumes that the newest inventory items are sold first. This method is less intuitive than FIFO in terms of physical flow, but it can have significant tax implications. During periods of inflation, LIFO results in a higher cost of goods sold, leading to lower taxable income. However, it’s important to note that LIFO is not permitted under International Financial Reporting Standards (IFRS).Let’s revisit the bakery example.

Under LIFO, the cost of goods sold for the 15 loaves would be (10 loaves

- $2.50) + (5 loaves

- $2) = $35. The value of the remaining 5 loaves in ending inventory would be 5 loaves

- $2 = $10. Note the difference in cost of goods sold and ending inventory compared to FIFO.

Weighted-Average Cost

The weighted-average cost method calculates the average cost of all inventory items available for sale during a period. This average cost is then used to determine the cost of goods sold and the value of ending inventory. This method simplifies inventory costing and reduces the impact of price fluctuations compared to FIFO and LIFO.Using the bakery example again, the total cost of 20 loaves is (10 loaves

- $2) + (10 loaves

- $2.50) = $45. The weighted-average cost per loaf is $45 / 20 loaves = $2.25. If 15 loaves are sold, the cost of goods sold is 15 loaves

- $2.25 = $33.75, and the value of the remaining 5 loaves in ending inventory is 5 loaves

- $2.25 = $11.25.

Situations Where Each Method is Most Appropriate

FIFO is often preferred for businesses with perishable goods or where the physical flow of inventory accurately reflects the first-in, first-out principle. LIFO can be advantageous in inflationary environments for tax purposes (where permitted). The weighted-average cost method is suitable when the cost of tracking individual item costs is high or when a simplified approach is desired.

Comparison of Inventory Costing Methods

| Method | Cost of Goods Sold | Ending Inventory | Tax Implications (Inflationary Environment) |

|---|---|---|---|

| FIFO | Reflects cost of oldest inventory | Reflects cost of newest inventory | Lower cost of goods sold, higher taxable income |

| LIFO | Reflects cost of newest inventory | Reflects cost of oldest inventory | Higher cost of goods sold, lower taxable income (where permitted) |

| Weighted-Average Cost | Uses average cost of all inventory | Uses average cost of all inventory | Moderate impact on taxable income |

Tracking Inventory Levels

Maintaining accurate inventory levels is crucial for the smooth operation of any business. Insufficient stock can lead to lost sales and dissatisfied customers, while excess inventory ties up capital and increases storage costs. Effective inventory tracking allows businesses to optimize stock levels, minimize waste, and maximize profitability. This section will explore various methods for tracking inventory and demonstrate practical applications.

Methods for Tracking Inventory Levels

Businesses employ a range of methods to track inventory levels, each with its own advantages and disadvantages. The choice of method often depends on factors such as business size, the complexity of the inventory, and budget constraints. Manual systems are suitable for smaller businesses with limited inventory, while automated systems are more appropriate for larger enterprises with extensive product lines.

- Manual Counting: This involves physically counting each item in stock and recording the quantity. It’s simple and inexpensive but prone to errors and time-consuming, especially for large inventories.

- Automated Systems: These systems utilize barcode scanners, RFID tags, or other technologies to automatically track inventory movements. They offer greater accuracy and efficiency but require a significant upfront investment.

- Spreadsheet Software: Spreadsheet programs like Microsoft Excel or Google Sheets provide a flexible and cost-effective way to track inventory, particularly for smaller businesses. They allow for easy data entry, calculation of stock levels, and generation of reports.

Conducting a Physical Inventory Count

A physical inventory count, also known as a stocktake, is a crucial process for verifying the accuracy of inventory records. It involves physically counting every item in stock and comparing the results to the inventory records. Discrepancies need investigation and adjustment to ensure the records reflect the actual stock on hand. The process typically involves:

- Planning and Preparation: Defining the scope, assigning teams, gathering necessary equipment (counting sheets, scanners, etc.), and scheduling downtime.

- Counting: Systematically counting items, ensuring accuracy and double-checking counts.

- Reconciliation: Comparing the physical count to the inventory records, identifying discrepancies, and investigating the causes of any differences.

- Adjustment: Updating the inventory records to reflect the actual stock levels.

Importance of Regular Inventory Reconciliation

Regular inventory reconciliation is essential for maintaining accurate inventory records. It helps identify discrepancies between the physical count and recorded data, enabling timely adjustments and preventing stockouts or overstocking. This process also aids in detecting potential issues like theft, damage, or errors in data entry. Reconciliation frequency depends on the nature of the business and inventory turnover rate; high-volume businesses might require daily or weekly reconciliation, while others might suffice with monthly checks.

Using a Spreadsheet to Track Inventory Levels and Calculate Costs

Spreadsheets offer a simple yet effective way to manage inventory. By creating a well-structured spreadsheet, businesses can track stock levels, calculate costs, and generate reports. Key elements to include are product ID, product name, quantity on hand, unit cost, total cost, reorder point, and reorder quantity. Formulas can be used to automatically calculate total cost and trigger reorder alerts when stock falls below the reorder point.

Sample Spreadsheet Layout for Inventory Tracking

The following table demonstrates a simple spreadsheet layout for tracking inventory levels for a specific product line, say, “T-shirts”.

| Product ID | Product Name | Quantity on Hand | Unit Cost |

|---|---|---|---|

| TS001 | Blue T-shirt | 150 | $10 |

| TS002 | Red T-shirt | 200 | $12 |

| TS003 | White T-shirt | 100 | $10 |

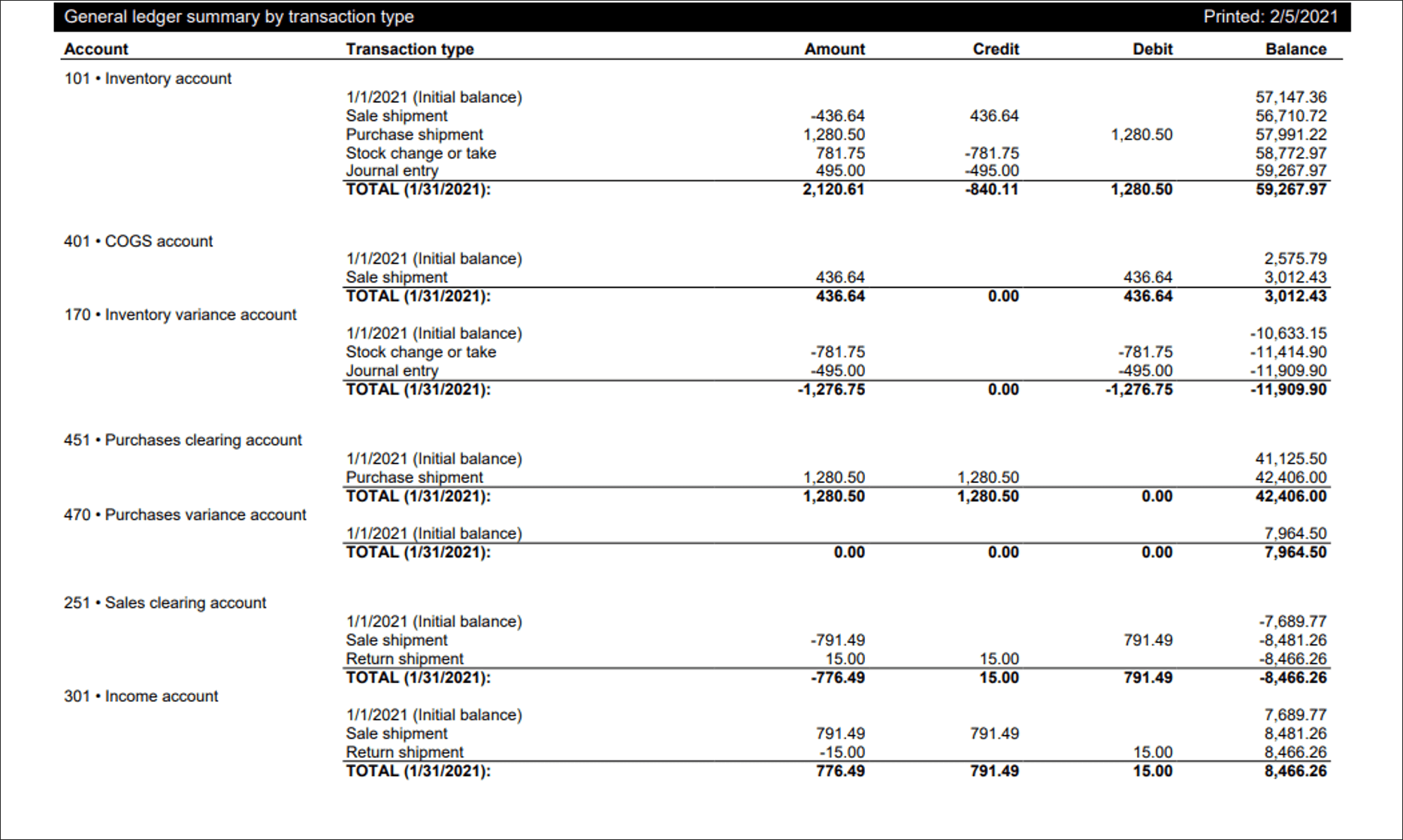

Inventory Valuation and Reporting

Accurate inventory valuation is crucial for a business’s financial health. It directly impacts the cost of goods sold (COGS), gross profit, net income, and ultimately, the company’s tax liability. Understanding different valuation methods and effectively reporting inventory data are essential for making informed business decisions and maintaining compliance.

Inventory Costing Methods

Several methods exist for calculating the value of inventory. The choice of method depends on factors such as the type of inventory, industry practices, and management preferences. The most common methods include First-In, First-Out (FIFO), Last-In, First-Out (LIFO), and Weighted-Average Cost.

- First-In, First-Out (FIFO): This method assumes that the oldest inventory items are sold first. The cost of goods sold is calculated using the cost of the oldest items, while the ending inventory reflects the cost of the most recent purchases. For example, if a company purchased 10 units at $10 each and later 15 units at $12 each, and sold 18 units, the COGS would be calculated as (10 units

– $10) + (8 units

– $12) = $208.The remaining inventory value would be (7 units

– $12) = $84. - Last-In, First-Out (LIFO): In contrast to FIFO, LIFO assumes that the newest inventory items are sold first. COGS is calculated using the cost of the most recent purchases, and the ending inventory reflects the cost of the oldest items. Using the same example, the COGS under LIFO would be (15 units

– $12) + (3 units

– $10) = $210, and the remaining inventory value would be (7 units

– $10) = $70. - Weighted-Average Cost: This method calculates the average cost of all inventory items available for sale during a period. This average cost is then used to determine both COGS and the value of ending inventory. In our example, the weighted average cost would be [(10 units

– $10) + (15 units

– $12)] / 25 units = $11.20 per unit. If 18 units were sold, the COGS would be 18 units

– $11.20 = $201.60, and the remaining inventory value would be 7 units

– $11.20 = $78.40.

Importance of Accurate Inventory Valuation for Financial Reporting, Business inventory book

Accurate inventory valuation is paramount for generating reliable financial statements. Overstating or understating inventory directly impacts the reported cost of goods sold, gross profit, and net income. This, in turn, affects key financial ratios used by investors, creditors, and other stakeholders to assess the financial health and performance of the business. Inaccurate inventory valuation can lead to misrepresentation of a company’s financial position and potentially result in legal and tax consequences.

Preparing an Inventory Report

Preparing an inventory report involves several steps:

- Data Collection: Gather data on all inventory items, including quantity on hand, unit cost, and location.

- Valuation: Apply the chosen costing method (FIFO, LIFO, or weighted-average) to determine the value of each inventory item.

- Categorization: Organize inventory by product category, location, or other relevant criteria.

- Report Generation: Create a report summarizing the key inventory metrics, including total value, quantity on hand, and cost of goods sold.

- Review and Analysis: Review the report for accuracy and identify any discrepancies or areas needing further investigation.

Common Inventory Reports

Businesses use various inventory reports to monitor and manage their inventory levels. Some common examples include:

- Inventory Turnover Report: This report shows how efficiently a business is selling its inventory.

- Stock Status Report: This report provides a snapshot of the current inventory levels for each item.

- ABC Analysis Report: This report categorizes inventory items based on their value and consumption rate, allowing businesses to prioritize management efforts.

- Inventory Aging Report: This report shows the age of inventory items, highlighting potential obsolescence or slow-moving items.

Inventory Report Template

| Item | Quantity on Hand | Unit Cost | Total Value |

|---|---|---|---|

| Product A | 100 | $10 | $1000 |

| Product B | 50 | $20 | $1000 |

| Product C | 200 | $5 | $1000 |

| Total | 350 | $3000 |

Inventory Control and Optimization: Business Inventory Book

Effective inventory control is crucial for profitability. Minimizing holding costs, preventing shrinkage, and optimizing stock levels are key to maximizing returns and maintaining a healthy business. This section explores strategies and best practices to achieve these goals.

Minimizing Inventory Holding Costs

High inventory levels tie up capital that could be used elsewhere in the business. Minimizing these costs involves a multifaceted approach. Strategies include implementing just-in-time (JIT) inventory systems, negotiating better terms with suppliers to reduce order minimums, and optimizing warehouse space to reduce storage fees. Regular inventory audits can also help identify slow-moving or obsolete items that contribute to unnecessary holding costs.

Careful forecasting and demand planning are essential to prevent overstocking, a significant contributor to these expenses. For example, a restaurant that accurately predicts customer demand for specific dishes can minimize food waste and storage costs associated with overstocking ingredients.

Common Inventory Management Challenges and Their Solutions

Businesses face various challenges in managing inventory effectively. Inaccurate inventory data, leading to stockouts or overstocking, is a common issue. Solutions include implementing robust inventory tracking systems, regular cycle counting, and employee training on proper inventory procedures. Another challenge is forecasting demand accurately. Sophisticated forecasting techniques, combined with historical sales data analysis, can improve prediction accuracy.

Supply chain disruptions also pose a significant threat. Diversifying suppliers and building strong relationships can mitigate this risk. Finally, integrating inventory management with other business systems, such as sales and purchasing, ensures data consistency and efficiency.

Benefits of Using Inventory Management Software

Inventory management software offers numerous benefits, significantly improving efficiency and accuracy. Automation of tasks such as tracking, ordering, and reporting frees up valuable employee time for other critical tasks. Real-time visibility into inventory levels allows for proactive decision-making, preventing stockouts and minimizing waste. Software also provides detailed reporting and analytics, offering insights into inventory performance and identifying areas for improvement.

Features like barcode scanning and automated ordering further enhance efficiency and reduce manual errors. For example, a small retail store using inventory management software could easily track sales, automatically reorder popular items when stock falls below a certain threshold, and generate reports on best-selling products, informing purchasing decisions and marketing strategies.

Preventing Inventory Shrinkage and Theft

Inventory shrinkage, encompassing loss due to theft, damage, or error, significantly impacts profitability. Implementing robust security measures, such as surveillance cameras and access control systems, is crucial. Regular cycle counting and physical inventory checks help identify discrepancies early on. Strong internal controls, including clear procedures for receiving, storing, and issuing inventory, minimize opportunities for theft. Employee training on proper inventory handling and security protocols is also vital.

Regular audits, both internal and external, provide an independent assessment of inventory control procedures and help identify weaknesses.

Tips for Optimizing Inventory Levels and Reducing Waste

Effective inventory optimization requires a multi-pronged approach.

- Implement a robust inventory tracking system.

- Utilize accurate forecasting techniques to predict demand.

- Regularly review and adjust safety stock levels.

- Analyze sales data to identify slow-moving or obsolete items.

- Implement a first-in, first-out (FIFO) inventory system to minimize waste.

- Negotiate favorable terms with suppliers to minimize order quantities.

- Employ just-in-time (JIT) inventory management where appropriate.

- Regularly conduct physical inventory counts to verify accuracy.

- Invest in employee training on inventory management best practices.

- Utilize inventory management software to automate tasks and improve efficiency.

Visual Representation of Inventory Data

Visualizing inventory data is crucial for effective inventory management. Charts and graphs provide a clear and concise way to understand complex data sets, revealing trends, patterns, and potential areas for improvement. This allows for quicker identification of issues and facilitates better decision-making.Transforming raw inventory data into compelling visuals helps stakeholders quickly grasp key performance indicators and overall inventory health.

This section will explore different chart types and their application in representing inventory information, along with a detailed example of illustrating inventory trends over time.

Bar Charts for Inventory Comparison

Bar charts are effective for comparing inventory levels across different products, categories, or time periods. Each bar represents a specific item or category, with the bar’s length corresponding to the quantity or value of the inventory. For instance, a bar chart could compare the stock levels of various product lines at the end of a fiscal quarter, allowing for immediate identification of best-selling and slow-moving items.

This allows for straightforward comparisons and highlights significant differences between inventory items.

Line Graphs for Tracking Inventory Trends

Line graphs are ideal for visualizing inventory trends over time. The x-axis represents time (e.g., months, quarters, years), and the y-axis represents the inventory level. The line connecting the data points shows the changes in inventory levels over the specified period. This visual representation easily highlights upward or downward trends, allowing for the identification of seasonal fluctuations or other patterns.

For example, a line graph could illustrate the stock levels of a specific product over a year, showing seasonal peaks and troughs in demand.

Pie Charts for Showing Inventory Composition

Pie charts effectively represent the proportion of different items within the total inventory. Each slice of the pie represents a specific item or category, with its size corresponding to its percentage of the total inventory value or quantity. This type of chart provides a quick overview of the inventory composition, highlighting the dominance of specific items and helping identify potential imbalances.

For example, a pie chart could show the percentage of total inventory value held by each product category, revealing whether a particular category is over- or under-represented.

Illustrating Inventory Levels Over Six Months

A sample chart depicting inventory levels of “Widget X” over a six-month period (January to June) could be constructed as follows: The x-axis would represent the months (January, February, March, April, May, June). The y-axis would represent the quantity of Widget X in stock. Data points would be plotted for each month, showing the inventory level at the end of each month.

For example: January (1000 units), February (1200 units), March (1500 units), April (1400 units), May (1100 units), June (900 units). A line would connect these data points, illustrating the trend of Widget X inventory over the six-month period. The chart title would be “Widget X Inventory Levels (Jan-Jun)”. Clear labeling of both axes ensures easy interpretation of the data presented.

Wrap-Up

Effective inventory management is the cornerstone of a successful business. By understanding the principles Artikeld in this guide, from basic record-keeping to sophisticated inventory costing and reporting, you can gain valuable insights into your business operations. Implementing the strategies discussed—whether using a simple spreadsheet or advanced inventory management software—will lead to improved efficiency, reduced waste, and ultimately, increased profitability.

The journey to mastering your inventory begins with a commitment to accuracy and a strategic approach to managing your assets. Embrace the power of informed decision-making and watch your business thrive.

General Inquiries

What is the difference between perpetual and periodic inventory systems?

Perpetual inventory systems track inventory levels continuously, while periodic systems update inventory counts at set intervals (e.g., monthly).

How often should I conduct a physical inventory count?

Frequency depends on business type and inventory turnover rate; monthly or quarterly counts are common for many businesses.

What are some common causes of inventory shrinkage?

Shrinkage can result from theft, damage, obsolescence, errors in record-keeping, or inaccurate physical counts.

How can I choose the right inventory costing method for my business?

The best method depends on factors like industry, inventory turnover, and tax implications. Consult with an accountant for guidance.