Step into the world of small business inventory control pro, where every item tells a story and every stock level holds the key to success. Get ready to dive into a realm of strategies, challenges, and best practices that will transform your inventory management into a symphony of efficiency.

In this guide, we’ll navigate the intricacies of inventory management, empowering you with the knowledge to overcome challenges like a pro and leverage technology to your advantage. So, fasten your inventory belts and prepare to embark on a journey that will elevate your stock control game to new heights.

Inventory Management Strategies for Small Businesses

Inventory management is the lifeblood of any small business. Without a solid inventory management system in place, businesses can quickly find themselves running out of stock, overstocking, or losing track of their inventory altogether. This can lead to lost sales, unhappy customers, and a lot of wasted time and money.

There are a number of different inventory management techniques that small businesses can use, but some of the most effective include:

- Just-in-time inventory:This method involves keeping only enough inventory on hand to meet current demand. This can help businesses reduce their carrying costs and free up cash flow.

- First-in, first-out (FIFO):This method assumes that the first items purchased are the first items sold. This can help businesses avoid having to sell outdated inventory at a loss.

- Last-in, first-out (LIFO):This method assumes that the last items purchased are the first items sold. This can help businesses reduce their tax liability in periods of inflation.

In addition to implementing an inventory management system, small businesses can also take a number of other steps to improve their inventory management practices. These include:

- Regularly counting inventory:This helps businesses keep track of their inventory levels and identify any discrepancies.

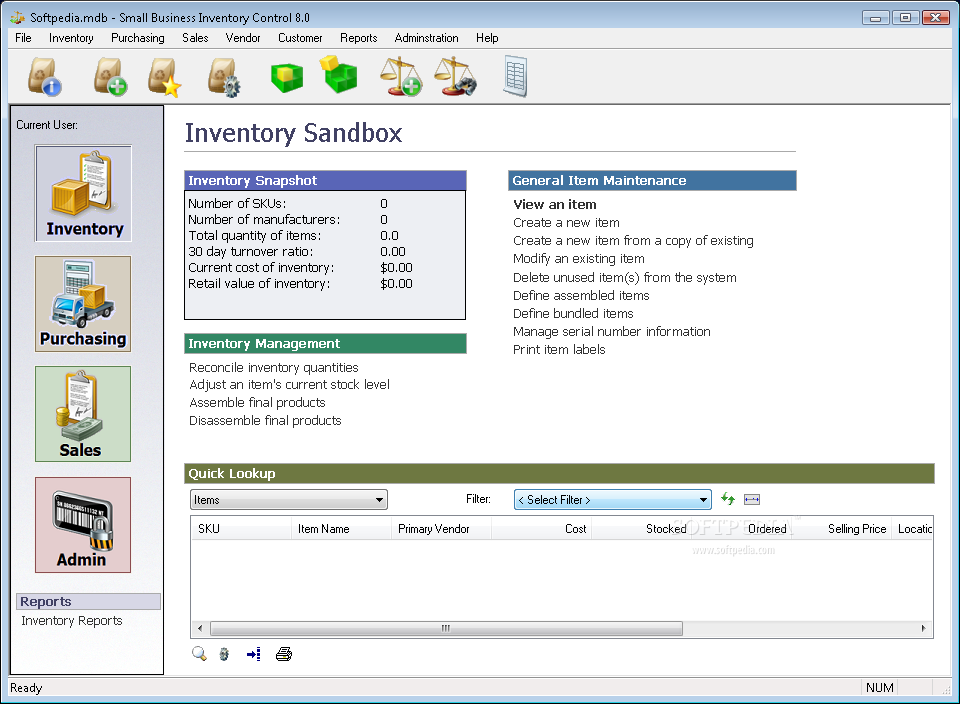

- Using inventory management software:This can help businesses automate their inventory management tasks and improve their accuracy.

- Training employees on inventory management procedures:This helps ensure that everyone in the business is following the same procedures and that inventory is being managed properly.

By following these tips, small businesses can improve their inventory management practices and save time, money, and headaches.

Common Inventory Management Challenges

Keeping track of inventory can be a headache for any small business. But don’t worry, we’re here to help! Here are some common inventory management challenges faced by small businesses and some tips on how to overcome them:

Overstocking

Overstocking is a common problem for small businesses. It can tie up your cash flow and lead to wasted inventory. To avoid overstocking, you need to carefully forecast demand and only order the inventory you need.

Understocking

Understocking is another common problem for small businesses. It can lead to lost sales and unhappy customers. To avoid understocking, you need to make sure you have enough inventory on hand to meet demand.

Inaccurate Inventory Records

Inaccurate inventory records can lead to a number of problems, including overstocking, understocking, and lost inventory. To avoid inaccurate inventory records, you need to use a reliable inventory management system and regularly reconcile your inventory records with your physical inventory.

Technology

Technology can be a great help in managing inventory. There are a number of software programs available that can help you track inventory, forecast demand, and generate reports. If you’re struggling to manage your inventory, consider investing in a software program.

Best Practices for Inventory Control

Inventory control is a crucial aspect of small business success, ensuring optimal stock levels, reducing waste, and enhancing profitability. Establishing best practices is paramount, including cycle counting procedures, inventory reconciliation methods, and stock level optimization techniques.

Regular cycle counting involves physically verifying inventory quantities at predetermined intervals, ensuring accuracy and minimizing discrepancies. Inventory reconciliation involves comparing physical inventory counts with records, identifying and correcting any discrepancies.

Stock Level Optimization Techniques

Stock level optimization techniques aim to maintain optimal inventory levels, balancing customer demand with holding costs. Safety stock levels should be established to buffer against unexpected fluctuations in demand. Just-in-time inventory systems aim to minimize inventory holding costs by receiving inventory as close to the time of need as possible.

Economic order quantity (EOQ) models help determine the optimal quantity to order, minimizing total inventory costs.

Inventory Management Metrics

Inventory management metrics are essential for businesses to track their inventory levels, optimize their supply chain, and improve their profitability. These metrics provide valuable insights into how well a business is managing its inventory and can help identify areas for improvement.

Key Inventory Management Metrics

There are several key inventory management metrics that businesses should track, including:

- Inventory turnover ratio: This metric measures how quickly a business is selling its inventory. A higher inventory turnover ratio indicates that the business is efficiently managing its inventory and not holding on to excess stock.

- Days of inventory on hand: This metric measures how long it takes a business to sell its entire inventory. A lower number of days of inventory on hand indicates that the business is holding less inventory and is more efficient in its inventory management.

- Inventory accuracy: This metric measures how accurate a business’s inventory records are. A higher inventory accuracy rate indicates that the business has a good handle on its inventory and is able to track its inventory levels accurately.

- Inventory carrying costs: These costs include the costs of storing, handling, and financing inventory. Businesses should track their inventory carrying costs to ensure that they are not excessive and are in line with industry benchmarks.

Calculating and Tracking Inventory Management Metrics

Calculating and tracking inventory management metrics is essential for businesses to improve their inventory management practices. The following steps can be used to calculate and track these metrics:

- Gather data on inventory levels, sales, and costs.

- Use the formulas provided above to calculate the inventory management metrics.

- Track the metrics over time to identify trends and areas for improvement.

Importance of Using Metrics to Improve Inventory Management, Small business inventory control pro

Using inventory management metrics is essential for businesses to improve their inventory management practices. These metrics provide valuable insights into how well a business is managing its inventory and can help identify areas for improvement. By tracking these metrics, businesses can:

- Reduce inventory costs

- Improve customer service

- Increase profitability

Inventory Management in Specific Industries

The world of inventory management is vast and diverse, with each industry facing its own unique set of challenges and solutions. From the bustling aisles of retail stores to the intricate assembly lines of manufacturing plants, every business has its own inventory management dance to master.

In this section, we’ll explore the unique inventory management challenges and solutions for three key industries: retail, manufacturing, and healthcare.

Retail

Retailers face the constant challenge of balancing customer demand with the need to minimize inventory costs. With a wide range of products and unpredictable consumer behavior, retailers must employ sophisticated inventory management techniques to ensure they have the right products in the right place at the right time.

- Challenge:Managing seasonal fluctuations in demand

- Solution:Using data analytics to forecast demand and adjust inventory levels accordingly

- Challenge:Preventing stockouts

- Solution:Implementing safety stock levels and using automated reordering systems

- Challenge:Managing multiple sales channels

- Solution:Using omnichannel inventory management systems to track inventory across all channels

Manufacturing

Manufacturers face a different set of inventory management challenges. They must balance the need for raw materials with the production schedule and the finished goods inventory. Managing inventory levels efficiently is crucial to avoid production delays and minimize waste.

- Challenge:Managing complex supply chains

- Solution:Using supply chain management software to track inventory levels and optimize transportation

- Challenge:Minimizing waste

- Solution:Implementing just-in-time inventory management techniques to reduce inventory holding costs

- Challenge:Forecasting demand for finished goods

- Solution:Using sales data and market research to predict future demand

Healthcare

Healthcare providers face unique inventory management challenges due to the critical nature of their products. They must ensure they have the right medical supplies and medications on hand to meet patient needs while also minimizing waste and preventing shortages.

- Challenge:Managing perishable inventory

- Solution:Using inventory management systems with temperature monitoring and expiration tracking

- Challenge:Preventing medication errors

- Solution:Implementing barcode scanning and other technology to ensure accuracy

- Challenge:Managing inventory across multiple locations

- Solution:Using centralized inventory management systems to track inventory levels at all facilities

Case Studies and Success Stories

Let’s delve into the realm of small businesses that have mastered the art of inventory control, like culinary ninjas slicing through a mountain of carrots.

These businesses have transformed their inventory management into a symphony of efficiency, reducing costs and boosting profits like a rocket ship on a sugar high.

Sweet Success: The Tale of the Cupcake Empire

Cupcake Corner, a humble bakery, faced a sweet dilemma: too many cupcakes going stale, and not enough to meet the sugar cravings of their loyal customers. Enter their inventory control wizardry.

- Inventory Tracking Made Easy:They implemented a digital inventory system that tracked every cupcake’s journey from batter to frosting.

- Predictive Analytics:They crunched data to forecast demand, ensuring they had just the right amount of cupcakes on hand to avoid waste and keep customers happy.

- Smart Replenishment:They automated cupcake replenishment based on real-time inventory levels, ensuring a steady supply without overstocking.

The result? Cupcake Corner’s profits soared like a sugar-induced high, with reduced waste and increased customer satisfaction. They became the talk of the town, known not only for their delectable cupcakes but also for their inventory management prowess.

Inventory Management Trends and Innovations: Small Business Inventory Control Pro

The world of inventory management is constantly evolving, with new trends and innovations emerging all the time. These trends are having a major impact on small businesses, and it’s important to be aware of them in order to stay ahead of the curve.

One of the most important trends in inventory management is the rise of cloud-based solutions. These solutions allow businesses to manage their inventory from anywhere, at any time. This can save businesses a lot of time and money, and it can also help them to improve their accuracy and efficiency.

Another important trend is the increasing use of data analytics in inventory management. Businesses are now able to collect and analyze data on their inventory levels, which can help them to identify trends and make better decisions. This can lead to significant savings in both time and money.

RFID Technology

Radio Frequency Identification (RFID) technology is becoming increasingly popular in inventory management. RFID tags can be attached to individual items, and they can be used to track the location and movement of those items. This can help businesses to improve their accuracy and efficiency, and it can also help them to reduce losses due to theft or damage.

Artificial Intelligence (AI)

Artificial Intelligence (AI) is also starting to play a role in inventory management. AI-powered systems can be used to automate tasks such as order processing and inventory forecasting. This can help businesses to save time and money, and it can also help them to improve their accuracy and efficiency.

Blockchain

Blockchain is a distributed ledger technology that is being used to improve the security and transparency of inventory management. Blockchain can be used to track the movement of goods from the supplier to the customer, and it can help to prevent fraud and counterfeiting.

These are just a few of the trends and innovations that are shaping the future of inventory management. As these trends continue to evolve, it’s important for small businesses to stay informed in order to take advantage of the latest opportunities.

Summary

As we bid farewell to the world of small business inventory control pro, remember that managing your stock is not just about numbers; it’s about orchestrating a harmonious flow of goods that keeps your business thriving. Embrace the strategies, overcome the challenges, and let technology be your ally.

With the knowledge you’ve gained, your inventory will sing in perfect harmony, ensuring a profitable and well-stocked future for your business.

Question & Answer Hub

What’s the secret to inventory management success?

Consistency and vigilance. Treat your inventory like a prized possession, keeping a watchful eye on stock levels and ensuring accuracy at every step.

How can I overcome inventory management challenges?

Embrace technology, seek expert advice, and never underestimate the power of a well-organized inventory system. Remember, challenges are stepping stones to inventory mastery.

Why is inventory management so crucial for small businesses?

It’s the backbone of your stock, ensuring you have the right products, in the right quantities, at the right time. It’s the key to happy customers, smooth operations, and a thriving business.